When a small company grows, the organisation needs to be split in some way, and commonly done was to divide the company into silos. If we look at it from an I-competence view, it is actually not a bad way to do it. Each manager is responsible for a group of I-shaped people and together the whole company has the respective I-competences needed for its business.

But, the problem that arise when the small company grows is that each manager needs to have employees represented in the projects, because that needed I-competence in the projects is the responsibility of the manager. So, even if many of the employees still have broad competence from the time the company was small, they will in the long term get specialised to work only within their manager’s area of responsibility. And new employees from start may only need the I-competence of the manager’s responsibility.

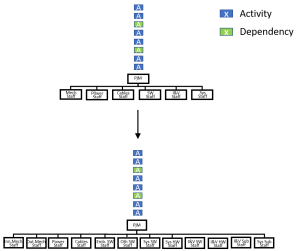

It can be depicted like this regarding what happens in the projects when a small company grows.

But, there is something wrong with that picture, because now we got a queue category problem. In an earlier blog post, we elaborated on Lean queues and Mean queues and now that knowledge come in handy. Because we have changed our Lean queue in the project for the small company, to a Mean queue in the big company. Why come? The reason is that in the big company solving the same task as the small company, we do not have full time resources anymore, which implies that we have to split all our resources with other projects. So, actually our Lean queue in the project, instead is put on the Line organisation, on newly born specialists that all projects need, which implies a Mean queue. And queueing theory for sure tell us that there will be waiting time in the Mean queues when many projects use the same specialist, so this will give us Activities in Queues waste, that will effect the Flow Efficiency negatively.

The control that we achieved with the introduction of projects, are somewhat lost again, putting Mean queues on the Line organisation, so this is how the picture should look like instead.

This is easily happening when a company grows larger, and the bigger company, the more specialists, the more Mean queues, which generates big problems with their Flow efficiency. Activities that should be handled are instead waiting for their turn at the specialist. And waiting time in queues are pure, pure waste. No customer will pay for low flow efficiency.

And as you already have seen, the example above is only with waterfall working. Just imagine the chaos if we also introduce parallel work with iterations.

But, a problem does not often come alone, and this time is no exception. Because, waste generated due to bad flow efficiency unfortunately also generates big resource efficiency waste. So, if there still are some doubtfulness to if Mean queues really are so bad, tomorrow’s blog post will definitely be a mind changer.