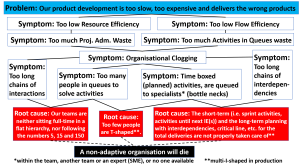

This is the wrap-up blog post of this series about Organisational Clogging, waste that we really need to avoid in our organisations, and as we have already seen in the former blog posts, the clogging comes from too many people and too many unhandled activities.

Here is our total picture of the chains of symptoms for the Organisational Clogging symptom in our Prefilled Problem Picture Analysis Map.

In the former blog posts in this series we have elaborated on silo organisations with projects or Agile development, Lean Production, Lean Product Development and also looked into the world of ants. Here is the summary and conclusions:

- Traffic congestions and queues to security controls are really treacherous examples when comparing it to Organisational Clogging in an organisation with for example Agile development. It is truly a simplistic example and make us lose focus on our own queue problems, and why we really have them.

- The traditional silo organisations with projects and Agile development organisations clog their organisations differently.

Silo organisations, too often specialise their people making the people to clog. Unfortunately, the specialisation of the people seems like the solution, so silo organisations specialise even more, all the way down to niching people, with extremely small part time resources clogging the projects, i.e. low Resource Efficiency.

Organisations with Agile development instead get clogged by too many Mean queues of activities with interdependencies, which gets a low Flow Efficiency. What is very scary about this, is that it is a whole industry trying to solve this queue symptom, even though it is not possible to solve symptoms, without sub-optimising our organisation. See this blog post about the sub-optimising WIP Limits.

Neither of these two Organisational Clogging problems are hard to solve, but probably the clogging of activities is the easiest one. The Agile teams do the HOW as usual, but not the WHAT and WHEN, that need always to be planned for the total delivery of all teams together, to avoid interdependencies between the teams and to common experts.

- The anti-clogging systems of ant not only shows that they efficiently remove Flow Efficiency waste, they also understand our Project Administration Waste and do not use part time ants unnecessarily.

- Lean Production takes very well care about the Organisational Clogging symptom, and solves its three root causes terrifically, giving an outstanding combination of Flow Efficiency, Resource Efficiency, low human strain and high quality.

- Also, in Lean Product Development, all three root causes are well taken care about, where the clogging of people is avoided over the years by introducing more and more T-shaped full-time positions in their projects making Toyota now having the following positions with very broad competences; Shusa (Chief Engineer), Product Development Engineer, Production engineer, Simultaneous Engineer, among others.

This was all for today.

Next “chapter” according to the Reading proposal tree is The continuation of filling in the Prefilled Problem Picture Analysis Map.

C u soon again.